Formulation and characterization of an analgesic ointment indicated for

pediatric use

Uttam Kumar Mandal*; Anis Arabi Hashmi; Bappaditya

Chatterjee

IKOP Sdn. Bhd., Kulliyyah of Pharmacy, International

Islamic University Malaysia (IIUM), Jalan Sultan Ahmad Shah, Bandar

Indera Mahkota, 25200, Kuantan, Pahang, Malaysia.

*

Corresponding author:

Dr. Uttam Kumar Mandal, HOD (R&D Department), IKOP Sdn. Bhd., Kulliyyah

of Pharmacy, International Islamic University Malaysia (IIUM), Jalan Sultan

Ahmad Shah, Bandar Indera Mahkota, 25200, Kuantan, Pahang Darul Makmu r, Malaysia.

E-mail: mandalju2007@gmail.com,

Mobile: +60 109062750, Fax: +60 9571 6775.

Abstract

This research work deals with formulation development and

characterization of an analgesic pediatric ointment. The ointment was

developed with menthol and camphor as active ingredients at lower

concentrations than used for an adult formulation. The formulation was

novel as it replaced the oleaginous hydrocarbon petroleum jelly base of

conventional ointment by olive oil, a more acceptable excipient to the

pediatric patients. The developed formulation was compared against

iKOOL, a commercial analgesic ointment with similar composition

produced by IKOP Sdn. Bhd., IIUM, Malaysia with respect to various

quality control tests. The developed formulation showed encouraging

results,but needs further investigation to convert it into a commercial

product.

Key words:

Analgesic ointment, Menthol, Camphor, Formulation development.

Running title:

Analgesic ointment formulation.

INTRODUCTION

As compared to oral administration, topical administration of analgesic

medicine provides some distinct and important advantages. It overcomes

gastric irritation and undesirable effects on cognition and level of

consciousness associated with its oral administration [1]. Topical

administration ensures a more even and continuous application of the dosage

for a long period directly to the site of the pain. Topical ointment

containing menthol and camphor has been used safely for many decades for

analgesic relief of minor aches and pains of muscles and joints [2-4].

Additionally, they are indicated for general relief and suppression of

common cold symptoms as cough, sore throat, nasal congestion together with

Their natural origin has helped them to be used commercially as safe and

efficacious as compared to their synthetic counterparts. Menthol (C 10H20O; molecular weight, 156; a terpene alcohol) is

obtained either from naturally occurring peppermint oil of synthesized by

hydrogenation of thymol. In lower concentrations (1% or less), menthol

depresses cutaneous sensory receptors, while at higher concentrations

(1.25% to 16%), it stimulates sensory receptors and thus it gives its

counter-irritant action [5]. Camphor (a terpenoid class of compound) is

obtained from the wood of Cinnamomum Camphora L. [2]. The

analgesic and counter irritant effect of camphor is quite established,

however its pharmacological mechanism is not yet fully understood [6]. In

one study, Moqrich et al. [7] found that camphor activates TRPV3, a member

of the transient receptor channel that causes excitation and

desensitization of sensory nerves. When menthol and camphor are used

together as analgesic, they provide synergistic action [8]. In few reports,

menthol was found to cause allergic contact dermatitis [9,10] and systemic

allergic reactions [11]. Camphor occurs in in two enantiomerform; natural

one is dextrorotatory (D-camphor), while the synthetic one form

laevorotatory (L-camphor). As compared to the natural one, synthetic

camphor is more toxic orally as claimed by toxicity study in mice [12].

There are many branded products, both as over-the-counter (OTC) and

prescription, in the form of ointment, liniment, and cream available in the

markets containing the active ingredients like menthol and camphor.

However, these commercial products contain high amount of active drugs (5

to 10% menthol and 5% camphor) as well as excipients. As a result, these

products are not safe when applied to the pediatric population. Topical

therapies, especially, analgesic and counter irritant medications that are

widely used for pediatric patients are often misused. Their unique type of

skin which is quite immature with respect to barrier property is more

susceptible to permeation of drugs as well as excipients as compared to the

adult skin; this may often lead to undesirable toxicity [13]. Skin surface

area to body weight ratio in infants and children is significantly higher

than the adults, which pose a great risk of accumulation of drugs in their

body. US Food and Drug Administration (FDA) does not entertain the use of

commonly prescribed topical medicines to pediatric patients as around 70%

of them are devoid of any pediatric labelling [13].

At this juncture, the objective of the present work was to explore the

feasibility of formulation and characterization of an ointment containing a

reduced amount of menthol (2% w/w) and camphor (2% w/w) for pediatric

patients. An attempt was made to reduce the amount mineral oil as ointment

base and replaced it with live oil. This was fundamentally proposed for

safety and patient compliance reasons, as olive oil is being historically

used to soothe baby skin rashes in addition to its well known skin

moisturizer effect. A analgesic ointment formulation, iKOOL produced by

IKOP Sdn Bhd., IIUM, Malaysia was used as reference formulation to compare

with the developed formulation.

MATERIALS & METHODS

Materials

Olive oil, menthol crystal, camphor, eucalyptus oil, and peppermint oil

were obtained as generous gift from IKOP Sdn., IIUM, Malayisa. For GC

analysis, camphor (≥95.50 %), and menthol (≥98.20 %) (Sigma-Aldrich, USA),

and petroleum benzine (boiling point 80 - 100 ⁰C) (Fischer scientific Co.,

UK) were generously donated by IKOP Sdn Bhd., Malaysia. Analgesic ointment

iKOOL used as reference sample was also obtained from IKOP Sdn. Bhd., IIUM,

Malaysia. Instrumental facility to prepare the ointment and characterize

like water bath, rotational viscometer, centrifuge, stability chamber, gas

chromatography etc were also provided by IKOP Sdn. Bhd.

Manufacturing Method

Composition of the ointment formulation is shown in Table 1. Water bath

(WNB 8 Memmert GmbH +Co. KG) was adjusted to 750 C. Beeswax and

olive oil were transferred in a glass beaker placed on that water bath.

Beeswax was allowed to melt and mixed with olive oil completely. Then

camphor was added to the mixture with consistent stirring. The mixture was

cooled down by lowering the bath temperature until 600C.

Immediately, menthol, eucalyptus oil, and peppermint oil were added to the

mixture and allowed to cool down to 280C until it forms an

ointment with the required consistency.

Table 1: C

omposition of the analgesic baby ointment.

|

Material name

|

Quantity (g/100g)

|

|

Olive oil

|

60 to 73%

|

|

Bees wax

|

17 to 30%

|

|

Menthol crystal

|

2

|

|

Camphor

|

2

|

|

Eucalyptus oil

|

3

|

|

Peppermint oil

|

3

|

|

Total

|

100gm

|

Optimization of the Ointment Base

In order to optimize the viscosity of the formulation, few experimental

trials were carried out with different ratios of beeswax and olive oil as

shown in Table 2. iKOOL ointment formulation prepared by IKOP Sdn. Bhd was

taken as the reference product to optimize the developed formulation.

Table 2:

Various experimental ratios of beeswax and olive oil for analgesic baby

ointment formulation.

|

Number of trials

|

Ointment base

|

|

Beeswax % (w/w)

|

Olive oil % (w/w)

|

|

1

|

30

|

60

|

|

2

|

25

|

65

|

|

3

|

20

|

70

|

|

4

|

15

|

75

|

|

5

|

17

|

73

|

Characterization of the Developed Ointment

Viscosity Measurement

The viscosity of the developed formulation was determined by Brookfield

Rotational Viscometer (DV-II+PRO Digital viscometer). A 200 ml test sample

was taken in a clean and dry 500 ml beaker and the viscosity of the test

sample was determined by using spindle no 6 at speeds of 20,50,100 and 150

r.p.m. During the measurement, the spindle was lowered upto a point where

the spindle does not hit the bottom of the beaker. The temperature was kept

uniform for all the test samples.

Centrifugation Stressed Test

The stability of the optimized formulated and the reference ointment

formulation was evaluated using the forced centrifugation test. This test

was carried out as per the method described by Baie & Sheikh [14]. Both

the formulations were subjected to speed ranged from (2000 to 14000) rpm

for 15 minutes in a centrifuge apparatus (Heraeus Megafuge 8 Centrifuge,

Fisher Thermo Scientific, Model No. FB15067) and phase separation of the

formulation, if any, was evaluated by visual observation.

Microbial Contamination Test

Developed ointment formulation was tested for both TAMC (total aerobic

microbial count) and TYMC (total combined yeast/mould count). An amount of

10 g of the sample was suspended in sodium chloride peptone solution (PH

7). One (1) ml of the prepared previous solution was added to a sterile

petri dish. Casein Soya bean digestive agar medium and sabouraud dextrose

agar were prepared for cultivation of bacteria and fungi respectively, by

pouring them into the prepared petri dishes. Then the petri dishes were

incubated at 300-350 for bacteria and 200

-250 for fungi for five days. One (1) ml of the buffered sodium

chloride was used as a negative control.

After the incubation period, colonies were counted using the manual colony

counter. Not more than 104 for bacteria and not more than 10 2 for fungi per gm /ml was considered as the limit of the

microbial contamination test .

Assay for the Developed Formulation for Menthol and Mamphor by Gas

Chromatography

Both the test and reference formulations were tested for the content of

menthol and camphor by gas chromatography method. According to USP

pharmacopeia, the formulation should contain not less than 90.0 percent and

not more than 110.0 percent of the labeled amounts. A Gas Chromatography

(GC) system (Agilent Technologies, 7890B GC System) The test was performed

according to the following procedure:

Preparation of Solutions:

Diluent: Petroleum benzene

Blank: 1ml of the diluent was transferred into GC vial after filtration

through 0.45 µm filter paper.

Standard stock solution of camphor and menthol: 1 g of camphor was weighted

and transferred into a 100ml volumetric flask, containing 60ml of diluent,

and after sonication takes place, the volume topped up with the diluent.

The same method was adopted for menthol stock preparation using 1g of the

menthol material.

Working Standard solution: 1 ml of both camphor and

menthol standard stock solution was transferred into 10ml volumetric flask

containing 5 ml diluent, mixed well and the volume was topped up, and

finally transferred into the GC vials after passing them through a 0.45 µm

membrane filter paper

Sample stock solution: 1 g of the ointment sample was transferred into

100ml volumetric flask containing 60ml diluent, then sonicated to ensure

sample dissolution, and make up the volume with diluent.

Working sample solution: 1 ml of the sample stock solution

is transferred into 10ml volumetric flask containing 5 ml diluent, mixed

well and the volume was topped up. Finally, they were transferred into GC

vial bypassing a µm 45.0 filter paper.

Chromatographic parameters:

GC detector: Flame ionization detector (FID)

Gas carrier: Helium

Column: VF-WAXms

Length: 30.0 m

Internal diameter: 250.00 µm

Film thickness: 0.25 µm

Mode: Split (Ratio 20:1)

Injection volume: 1µL

Run time: 14 Minute

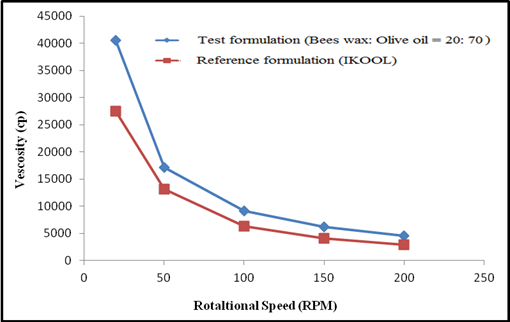

The content of active ingredient was calculated based on the following

equation:

…………..equation 1

…………..equation 1

Where, AT: Area of peak response due to analyte content in sample solution

AS: Area of peak response due to analyte content in standard solution

WT: Weight of sample taken

P: % of purity of analyte standard

Stability Study

An accelerated stability study was carried out according to the ICH

guidelines at 400C/75% RH. Due to time constraint, only one

sample of three months was analysed. The formulation was filled in the

aluminum collapsible tubes; physical appearance, viscosity, and drug assay

were analysed as evaluation parameters.

RESULTS AND DISCUSSION

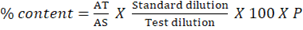

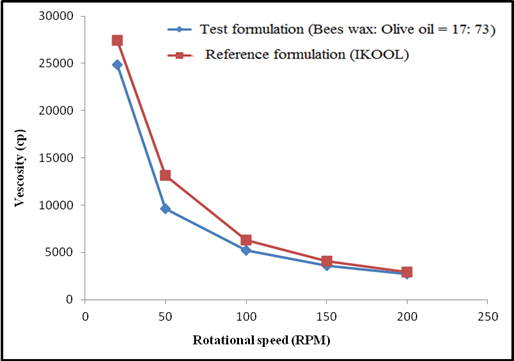

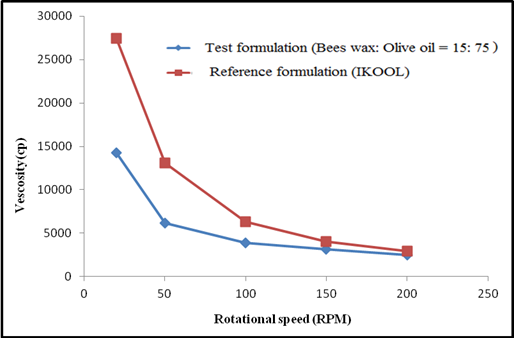

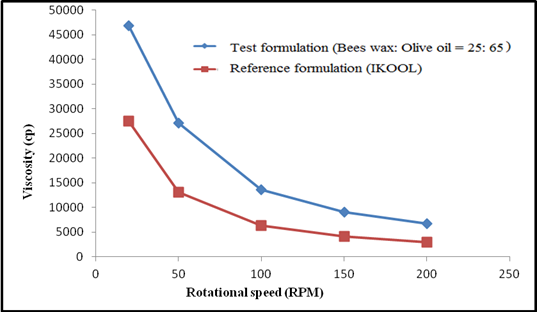

Several experimental trials were carried out to investigate the best ratio

of olive oil and beeswax for the required viscosity of the formulation. The

results are shown in Table 3 and Figure 1 to Figure 4 based on the highest

obtained torque values. It was found that the ratio of 17:73 w/w for

beeswax and olive oil was just enough to provide the required viscosity

like the reference product. The formulation with this composition of

beeswax and olive oil (17:73 w/w) was selected as the optimized

formulation. This selection was based on in its consistency and viscosity

resemblance to the commercial iKOOL formulation prepared by IKOP Sdn. Bhd.,

IIUM, Malaysia. The higher the concentration of beeswax, the higher was the

viscosity. The optimized formulation resulted comparable characterization

parameters in comparison with the commercial product. Table 4 shows the

results of centrifugation stressed test subjected to the optimized test and

reference formulation. As such, both the formulations resulted similar type

of physical stability profile; they withstand physical separation by

centrifugation force exerted at 6000 RPM for 15 minutes, initiate

separation at 8000 RPM, but completely separate at 10000 RPM. No bacteria

or fungi growth was revealed after microbial contamination test performed

on the optimized formulation. 3 months of accelerated stability study at

400C and 75% RH for three months showed good stability profile for the

optimized formulation. The formulation was physical stable without any kind

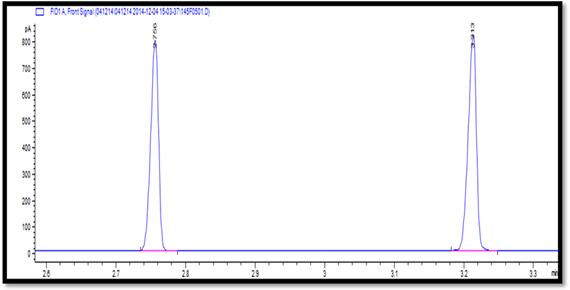

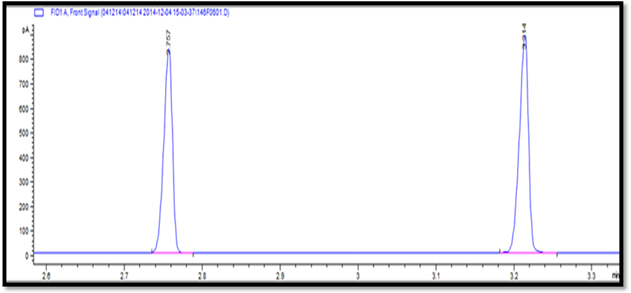

of phase separation. As evident from the GC chromatograms (Figure 5 and

Figure 6), menthol and champhor were well separated without any kind of

interference. Assay results for both active pharmaceutical ingredients

after 3 months of accelerated stability study is shown in Table 5. It

indicates that both camphor (2.12 %) and menthol (1.96 %) were within the

accepted range (±10% of the label claim) of their content percentage (2%

w/w).

Table 3:

Viscosity measurement results based on the highest obtained torque value.

|

Number

|

Ratio (bees wax /Olive oil)

|

Torque value / Speed

|

Viscosity value (cP)

|

|

1

|

(25:65)

|

93.6 / 20 r.p.m

|

46800.00

|

|

2

|

(20:70)

|

92.3 / 150 r.p.m

|

6153.33

|

|

3

|

(17:73)

|

53.9 / 150 r.p.m

|

3593.33

|

|

4

|

(15:75)

|

61.7 / 200 r.p.m

|

3085.00

|

|

5

|

iKOOL

|

65.6 / 50 r.p.m

|

13120.00

|

Figure 1:

Viscosity of test formulation (beeswax and olive oil ratio-17:73) and

reference formulation (iKOOL).

Figure 2:

Viscosity of test formulation (beeswax and olive oil ratio-15:75) and

reference formulation (iKOOL).

Figure 3:

Viscosity of test formulation (beeswax and olive oil ratio-20:70) and

reference formulation (iKOOL).

Figure 4:

Viscosity of test ointment (beeswax and olive oil ratio-25:65) and

reference product (Original iKOOL)

Table 4:

Results of centrifugation stressed test subjected to optimized test and

reference formulation.

|

Centrifugation speed

|

Observation

|

|

Optimized test formulation

|

Reference formulation

|

|

2000

|

No separation

|

No separation

|

|

4000

|

No separation

|

No separation

|

|

6000

|

No separation

|

No separation

|

|

8000

|

Slight separation

|

Slight separation

|

|

10000

|

separation

|

Separation

|

|

12000

|

separation

|

Separation

|

|

14000

|

separation

|

Separation

|

Table 5:

Assay results for menthol and camphor analytical results in mix standard

and optimized test formulation after 3 months of accelerated stability

study.

|

Sample identity

|

Retention Time

(minutes)

|

Area

|

Height

|

Width

|

Area

|

Symmetry

factor

|

|

Menthol in mixed standard

|

2.756

|

620.5

|

773.2

|

0.0124

|

47.821

|

1.132

|

|

Menthol in test sample

|

2.757

|

642.9

|

791.1

|

0.0135

|

46.748

|

1.112

|

|

Camphor in mixed standard

|

3.213

|

677.1

|

788.7

|

0.013

|

52.179

|

1.192

|

|

Camphor in test sample

|

3.214

|

732.3

|

835.2

|

0.0142

|

53.252

|

1.193

|

Figure 5:

Representative GC chromatograms showing the separation of menthol (2.758

minutes) and camphor (3.213 minutes) in mix standard.

Figure 6:

Representative GC chromatograms showing the separation of menthol (2.757

minutes) and camphor (3.214 minutes) in test sample subjected to 3 months

accelerated stability study.

CONCLUSION

An optimized analgesic ointment formulation with a composition of 2%

menthol and 2% camphor together with beeswax and olive oil mixture (17: 73

w/w) as a base was developed for pediatric patients. The various evaluation

parameters carried out to assess the quality of the

developed pediatric ointment formulation and they showed satisfactory

results when compared with the reference iKOOL ointment prepared by IKOP

Sdn. Bhd, IIUM, Malaysia. The viscosity of the optimized formulation was

also satisfactory when compared with the reference product. Moreover, the

assay results for both the active ingredients after a period of 3 months

accelerated stability study was within the accepted range for the active

pharmaceutical ingredients. The developed analgesic pediatric ointment

containing menthol and camphor may be further investigated to commercialize

in future as a replacement of the conventional analgesic ointments

available in the market.

REFERENCES

[1] H.K. Archer, M.S. Pettit, Analgesic and antiphlogistic compositions and

therapeutic wrap for topical delivery, U.S. Patent No. 5, 976, 547.

Washington, DC: U.S. Patent and Trademark Office, 1999.

[2] P. Zuccarini, Camphor: risks and benefits of a widely used natural

product, J. Appl. Sci. Environ. Manag. 3 (2009) 69-74.

[3] C. Gaudioso, J. Hao, M.F. Martin-Eauclaire, M. Gabriac, P. Delmas,

Menthol pain relief through cumulative inactivation of voltage-gated sodium

channels, Pain 153 (2012) 473-484.

[4] P. Johar, V. Grover, R. Topp, D.G. Behm, A comparison of topical

menthol to ice on pain evoked tetanic and voluntary force during delayed

onset muscle soreness, Int. J. Sports Phys Ther. 7 (2012) 314-322.

[5] T. Patel, Y. Ishiuji, G. Yosipovitch, Menthol: a refreshing look at

this ancient compound, J. Am. Acad. Dermatol. 57 (2007) 873-878.

[6] H. Xu, N.T. Blair, D.E. Clapham, Camphor activates and strongly

desensitizes the transient receptor potential vanilloid subtype 1 channel

in a vanilloid-independent mechanism, J. Neurosci. 25 (2005) 8924-8937.

[7] A. Moqrich, S.W. Hwang, T.J. Earley, M.J. Petrus, A.N. Murray, K.S.

Spencer, M. Andahazy, G.M. Story, A. Patapoutian, Impaired thermosensation

in mice lacking TRPV3, a heat and camphor sensor in the skin, Science 307

(2005) 1468-1472.

[8] T.M. Wang, L.Q. Ding, H.J. Jin, R. Shi, J.S. Wu, L. Zhu, Y.Q. Jia, Y.M.

Ma, Simultaneous quantification of multiple volatile active components in

rat plasma using a headspace-solid phase dynamic extraction method coupled

to gas chromatography-tandem mass spectroscopy: application in a

pharmacokinetic study of Longhu Rendan pills, RSC Adv. 5 (2015)

29631-29638.

[9] A. Aguirre, J.M. Oleaga, R. Zabala, R. Izu, J.L. Díaz‐Pérez, Allergic

contact dermatitis from Reflex® spray, Contact Derm. 30 (1994)

52-53.

[10] S.M. Wilkinson, M.H. Beck, Allergic contact dermatitis from menthol in

peppermint, Contact Derm. 30 (1994) 42-43.

[11] E.M. McGowan, Menthol urticarial, Arch. Dermatol. 94 (1966) 62–63.

[12] N. Chatterjie, G.J. Alexander, Anticonvulsant properties of

spirohydantoins derived from optical isomers of camphor, Neurochem. Res. 11

(1986)1669-1676.

[13] D.W. Metry, A.A. Hebert, Topical therapies and medications in the

pediatric patient, Pediatr. Clin. North Am. 47 (2000) 867-876.

[14] S. H. Baie, K.A. Sheikh, The wound healing properties of Channa

striatus-cetrimide cream-wound contraction and glycosaminoglycan

measurement, J. Ethnopharmacol. 73 (2000) 15-30.